Combo

Welcome to the future of cutting technology.

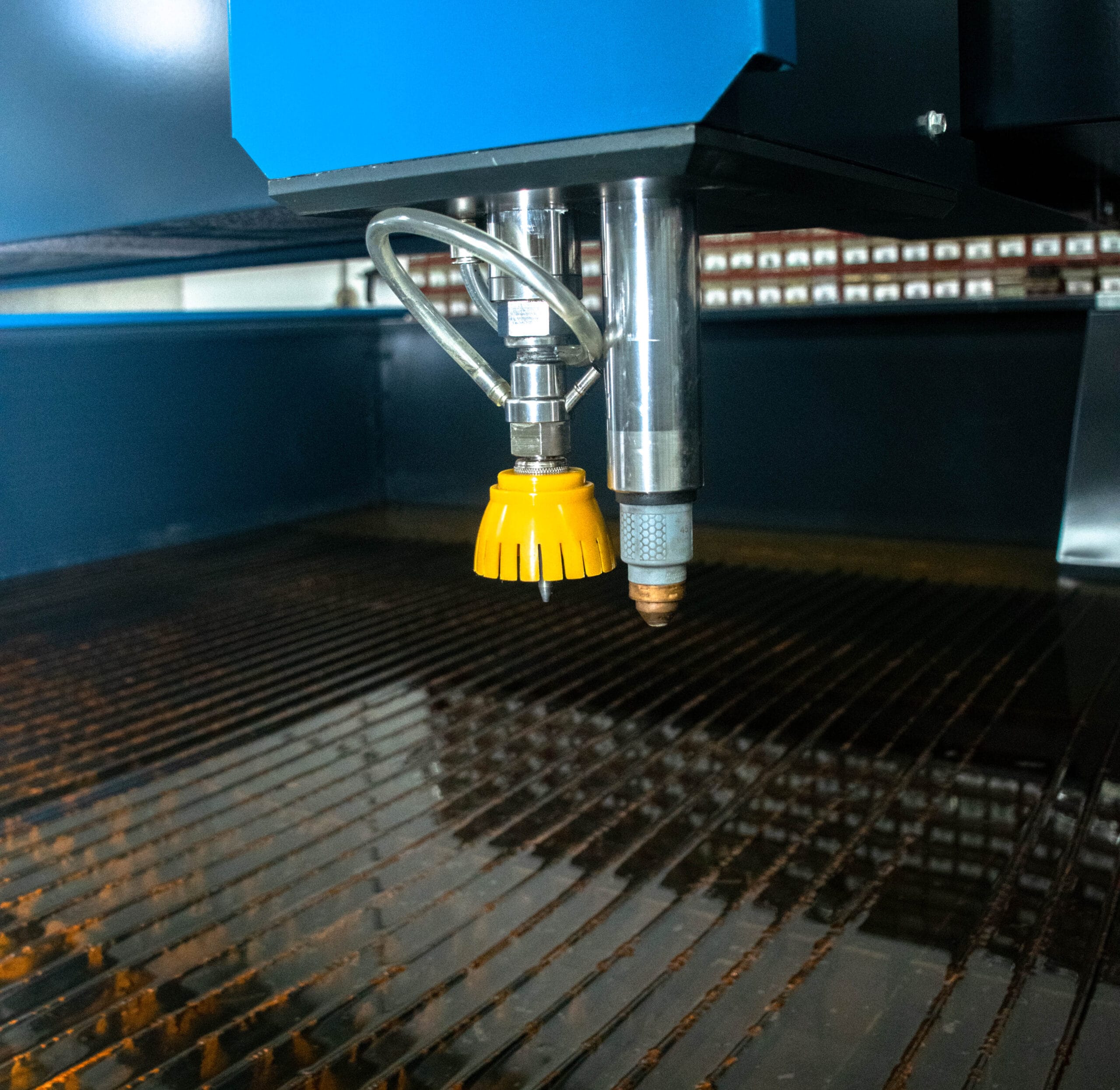

Introducing our innovative Combo machine—a harmonious fusion of dual-nozzle waterjet and plasma cutting technologies designed to redefine precision and versatility. Crafted with groundbreaking dual nozzle engineering, it delivers unparalleled performance across metals, composites, and beyond.

Every facet—from its meticulously engineered dual-nozzle system ensuring pristine, pipe-free aesthetics to the smart integration of both waterjet and plasma heads—has been developed to meet the rigorous demands of modern fabrication. The intelligent, dual-mode configuration offers effortless transition between cutting methods, ensuring each cut is executed with extraordinary finesse.

Experience the future of fabrication with a machine where form and function converge flawlessly. The Combo machine redefines efficiency and precision, transforming every cut into a work of art and engineering excellence.

A precision-engineered system combining waterjet and plasma technologies, offering seamless transitions between heads. This synergy delivers unmatched flexibility, optimizing cutting speed and quality for a wide range of materials.

Each head operates with dedicated control, allowing simultaneous or selective use for different tasks. Whether rough plasma cuts or fine waterjet detailing, the system adapts instantly to the job’s complexity.

Smart sensors and adaptive controls analyze material types and thicknesses in real time, automatically adjusting cutting parameters. This ensures optimal performance across metals, alloys, composites, and layered materials.

A precision-engineered system combining waterjet and plasma technologies, offering seamless transitions between heads. This synergy delivers unmatched flexibility, optimizing cutting speed and quality for a wide range of materials.

Each head operates with dedicated control, allowing simultaneous or selective use for different tasks. Whether rough plasma cuts or fine waterjet detailing, the system adapts instantly to the job’s complexity.

Smart sensors and adaptive controls analyze material types and thicknesses in real time, automatically adjusting cutting parameters. This ensures optimal performance across metals, alloys, composites, and layered materials.

Technical Specifications

| Model | Models available | X-axis travel (mm) | Y-axis travel (mm) | Z-axis travel (mm) | Max. speed (m/min) | Linear Accuracy (mm) | Repeatability (mm) | Pump/Unit/Spindle Motor | Footprint (m)* |

| Combo | 4021-Combo | 4100 | 2100 | 200 | 25 | +/- 0.03 | +/- 0.02 | Jekran Pump model 22/30 22/30kW - 3 phase - 3,800bar Hypertherm or GYS | 8.5x3.4 |

| Combo | 6021-Combo | 6100 | 2100 | 200 | 25 | +/- 0.03 | +/- 0.02 | Jekran Pump model 22/30 22/30kW - 3 phase - 3,800bar Hypertherm or GYS | 10.5x3.4 |

*Note: The footprint dimensions are only a guideline. The HP pump, bulk hopper, garnet removal structure, and console can be positioned differently to fit the workspace available to our customers.

Pump Technical Specifications

| Model 22 Direct Drive | Model 30 Direct Drive | |

| Electric Servo Motor Power | 30 HP (22 kW) | 40 HP (30 kW) |

| Efficiency | ≥ 90% | ≥ 90% |

| Output Pressure PSI | 58,000 psi | 58,000 psi |

| Output Pressure Bar | 4000 Bar | 4000 Bar |

| Orifice & Flow Rate | 0.011" / 0.82 gpm (0.3 mm / 3.1 lpm) | 0.014" / 1.1 gpm (0.35 mm / 4.2 lpm) |

| Footprint LxWxH | 43.7" x 31" x 42"(1110 mm x 800 mm x 1065 mm) | 43.7" x 31" x 42"(1110 mm x 800 mm x 1065 mm) |

FAQs

What is the Jekran Combo machine?

It’s a dual‑mode cutting system that combines waterjet and plasma technologies in one machine, allowing you to switch seamlessly between precision waterjet cutting and high‑speed plasma cutting.

What are the main advantages of combining waterjet and plasma cutting?

You get maximum versatility — plasma for fast, economical cuts on conductive metals, and waterjet for intricate, heat‑free cuts on metals, composites, and non‑conductive materials.

How does the dual‑nozzle system work?

Each cutting head has independent control, so you can operate them separately or simultaneously, adapting instantly to different materials or stages of production.

Which materials can the Combo machine cut?

It handles metals, alloys, composites, layered materials, and more, thanks to adaptive sensors that adjust cutting parameters in real time.

How accurate is the Combo system?

It offers ±0.03 mm linear accuracy and ±0.02 mm repeatability, ensuring consistent, high‑precision results.

What pump and plasma options are available?

You can choose between 22 kW or 30 kW direct‑drive waterjet pumps (up to 58,000 psi / 4,000 bar) and plasma units from Hypertherm or GYS.

Do you provide installation, training, and after‑sales support?

Yes — we offer on‑site installation, operator training, preventive maintenance, and global technical support to keep your system running at peak performance.