5-Axis

Welcome to the future of cutting technology.

Our advanced 5-Axis machine transforms every cut into a masterpiece of engineering. Designed with industry-first innovations, it offers unparalleled accuracy across metals, composites, and ceramics.

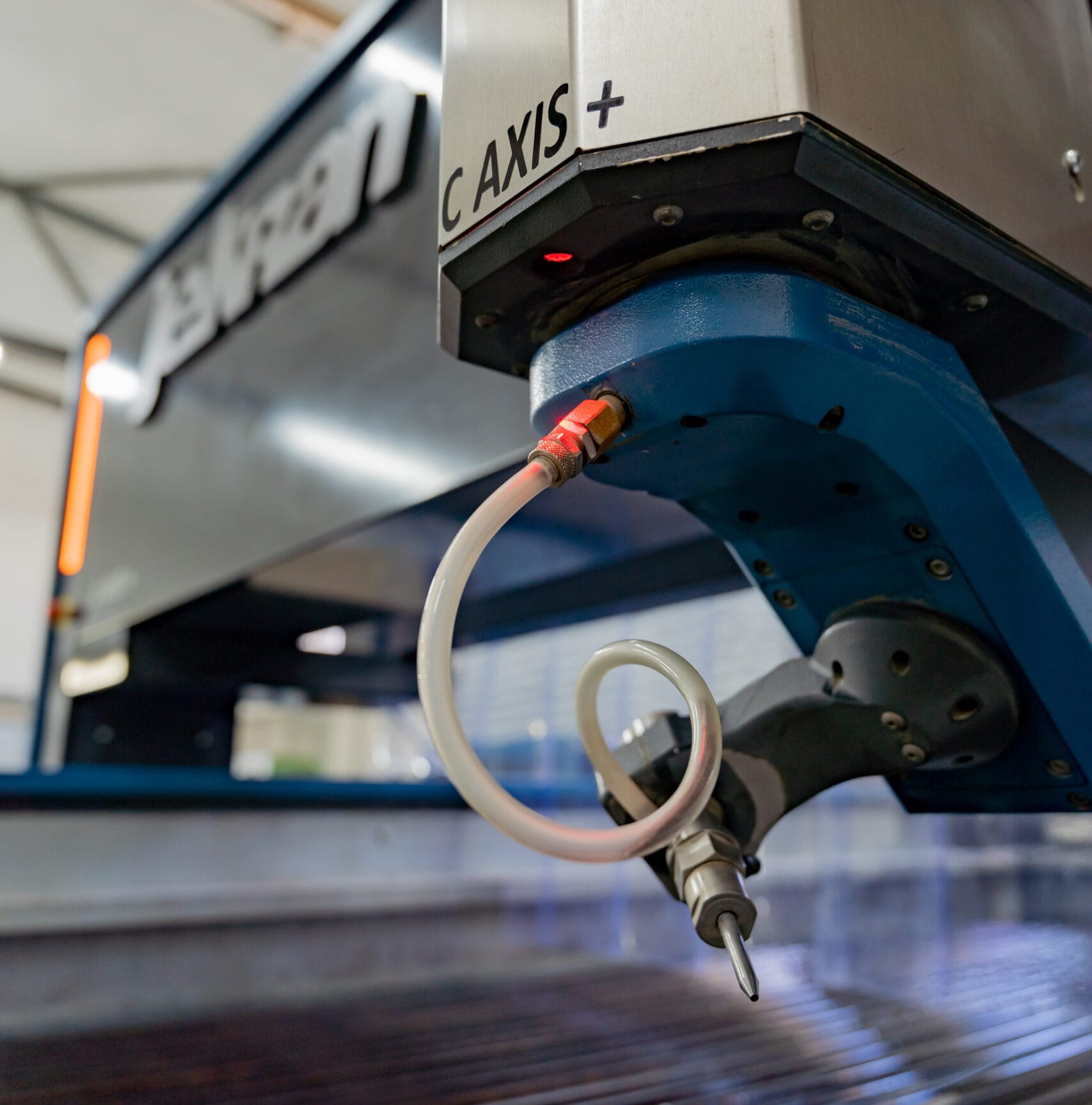

Every element—from our revolutionary nozzle design that achieves a pristine, pipe-free aesthetic, to the seamlessly integrated camera and probing systems—has been engineered to exceed the demands of modern fabrication.

With dynamic 5-axis control, even the most intricate cuts become effortless. The machine’s clean lines, intuitive controls, and precision components forge a solution where form and function converge.

Experience a new era of performance, where each detail is crafted to deliver consistent, award-winning results.

A breakthrough design that eliminates external pipes, offering simplicity in appearance and maintenance while ensuring peak performance.

Advanced camera systems work in real time with probing technology to optimize every cut, delivering unmatched precision through dynamic adjustments.

Expertly engineered to cut an expansive range of materials—from metals, composites, and ceramics to stone, glass, plastics, and more—our 5-Axis solution rises to the challenge of virtually any production environment with ease.

A breakthrough design that eliminates external pipes, offering simplicity in appearance and maintenance while ensuring peak performance.

Advanced camera systems work in real time with probing technology to optimize every cut, delivering unmatched precision through dynamic adjustments.

Expertly engineered to cut an expansive range of materials—from metals, composites, and ceramics to stone, glass, plastics, and more—our 5-Axis solution rises to the challenge of virtually any production environment with ease.

Technical Specifications

| Model | Models available | X-axis travel (mm) | Y-axis travel (mm) | Z-axis travel (mm) | Max. speed (m/min) | Linear Accuracy (mm) | Repeatability (mm) | Pump/Unit/Spindle Motor | Footprint (m)* |

| 5-Axis | 4021-5AXG | 4100 | 2100 | 200 | 25 | +/- 0.02 | +/- 0.02 | Jekran Pump model 22/30 22/30kW - 3 phase - 3,800bar | 8.5x3.4 |

| 5-Axis | 6021-5AXG | 6100 | 2100 | 200 | 25 | +/- 0.02 | +/- 0.02 | Jekran Pump model 22/30 22/30kW - 3 phase - 3,800bar | 10.5x3.4 |

*Note: The footprint dimensions are only a guideline. The HP pump, bulk hopper, garnet removal structure, and console can be positioned differently to fit the workspace available to our customers.

Pump Technical Specifications

| Model 22 Direct Drive | Model 30 Direct Drive | |

| Electric Servo Motor Power | 30 HP (22 kW) | 40 HP (30 kW) |

| Efficiency | ≥ 90% | ≥ 90% |

| Output Pressure PSI | 58,000 psi | 58,000 psi |

| Output Pressure Bar | 4000 Bar | 4000 Bar |

| Orifice & Flow Rate | 0.011" / 0.82 gpm (0.3 mm / 3.1 lpm) | 0.014" / 1.1 gpm (0.35 mm / 4.2 lpm) |

| Footprint LxWxH | 43.7" x 31" x 42"(1110 mm x 800 mm x 1065 mm) | 43.7" x 31" x 42"(1110 mm x 800 mm x 1065 mm) |

FAQs

What is a 5‑Axis cutting machine?

A 5‑Axis cutting machine moves the cutting head along the X, Y, Z axes plus two additional rotational axes, allowing for complex, angled, and contoured cuts in a single setup — ideal for intricate parts and multi‑material projects.

What makes Jekran’s 5‑Axis machine different from others?

Our 5‑Axis solution features revolutionary nozzle engineering with a pipe‑free design for cleaner aesthetics and easier maintenance, plus integrated camera and probing systems for real‑time precision adjustments.

Which materials can the 5‑Axis machine cut?

It can process metals, composites, ceramics, stone, glass, plastics, and more, making it suitable for a wide range of industries from aerospace to architectural fabrication.

How accurate is the Jekran 5‑Axis system?

With linear accuracy and repeatability of ±0.02 mm, it delivers micron‑level precision even on complex geometries.

What are the available size options?

Standard models include the 4021‑5AXG (4100 × 2100 mm cutting area) and 6021‑5AXG (6100 × 2100 mm), with custom configurations available to fit your workspace.

What pump options are available?

We offer 22 kW and 30 kW direct‑drive pumps delivering up to 58,000 psi (4,000 bar), ensuring optimal cutting performance for different materials and thicknesses.

Does the 5‑Axis machine support automated adjustments?

Yes. The integrated camera and probing systems work in real time to optimize cutting paths, ensuring consistent quality and reducing setup time.

Do you provide installation, training, and support for the 5‑Axis machine?

Absolutely. We offer on‑site installation, operator training, preventive maintenance plans, and global technical support to keep your system running at peak performance.