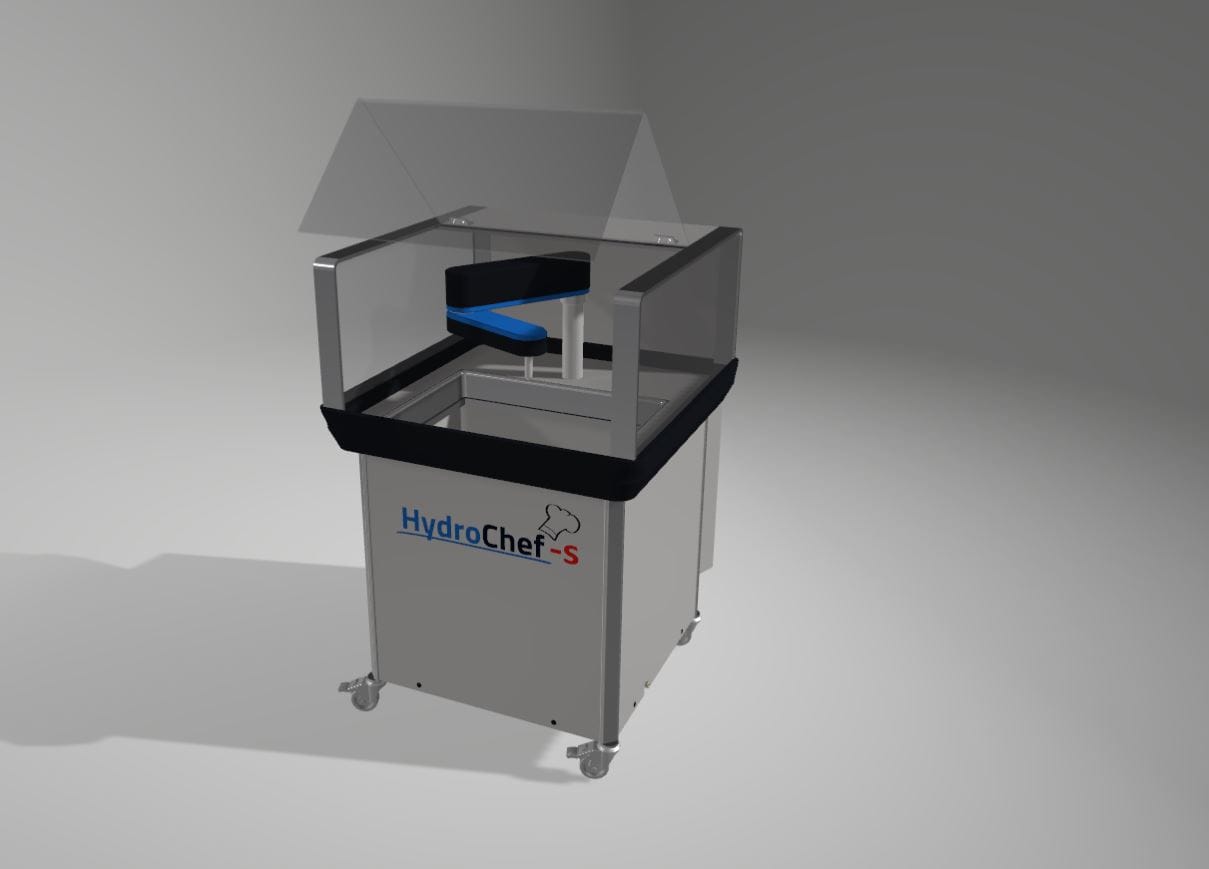

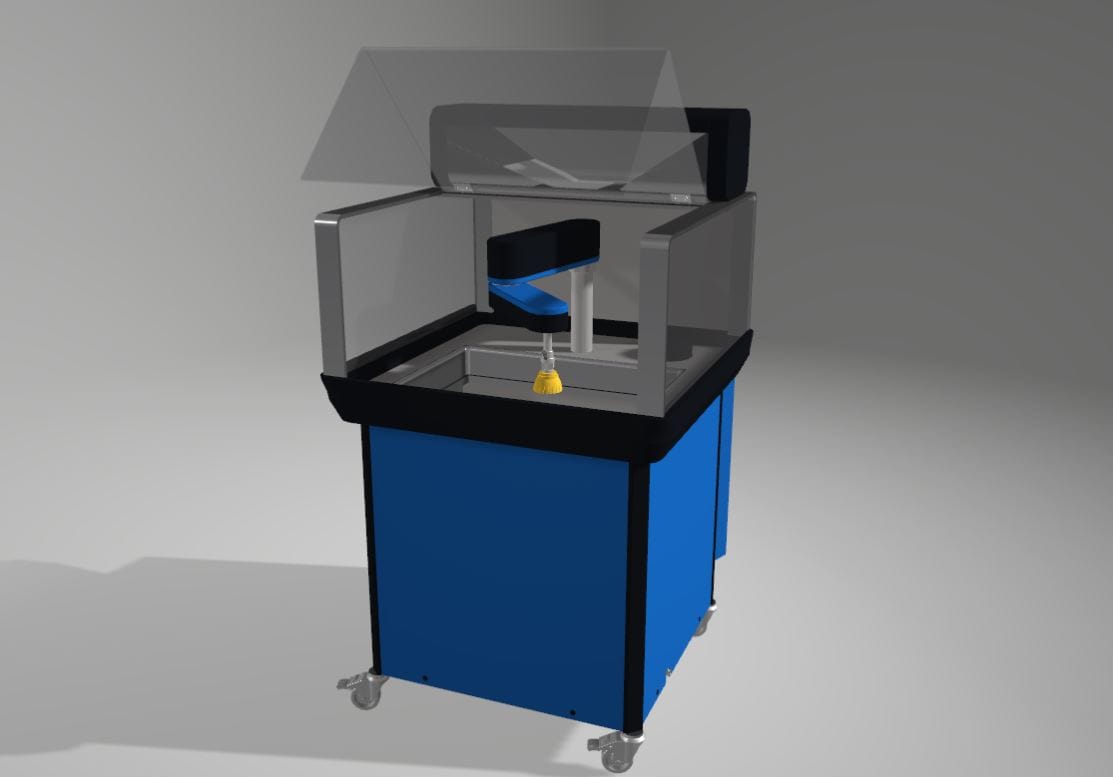

We design and build high‑precision waterjet, plasma, CNC router, and laser cutting machines, as well as OEM accessories. Our solutions are engineered for industries ranging from metal fabrication and aerospace to stone, glass, and food processing.

Yes. While we have proven standard models, every Jekran machine can be custom‑engineered to meet your exact material, size, and performance requirements.

All our machines are designed, engineered, and assembled in Malta, with components sourced from a trusted global network.

Depending on the technology, our machines can cut metals, composites, stone, ceramics, plastics, glass, wood, and even food products with precision.

• Waterjet – Cold cutting, ideal for heat‑sensitive materials, capable of cutting virtually any material.

• Plasma – High‑speed cutting for conductive metals, cost‑effective for thicker materials.

• Router – Precision milling and shaping for wood, plastics, and softer metals.

• Laser – Ultra‑fine, high‑speed cutting for metals, plastics, and thin materials with minimal kerf.

Yes. We offer on‑site installation and operator training to ensure your team can use the machine efficiently from day one.

We provide remote diagnostics, on‑site servicing, spare parts supply, and software updates to keep your machine performing at its best.

Absolutely. We serve clients worldwide, offering both remote assistance and global on‑site service.

Our engineering team will assess your materials, production volume, tolerances, and budget to recommend the most suitable solution.

Yes. We can adapt bed size, cutting head type, pump pressure, and automation features to your requirements.

With proper maintenance, our machines are built to deliver decades of reliable service.

Yes. We stock a full range of OEM parts, cutting heads, nozzles, and consumables for all our machines.

Service intervals depend on usage, but we recommend regular preventive maintenance to maximize uptime and accuracy.

Our solutions are trusted in metal fabrication, aerospace, automotive, stone and tile, signage, glass processing, food production, and more.

Reach out to us—because every question deserves a precise answer.