Smart Digital Fabrication

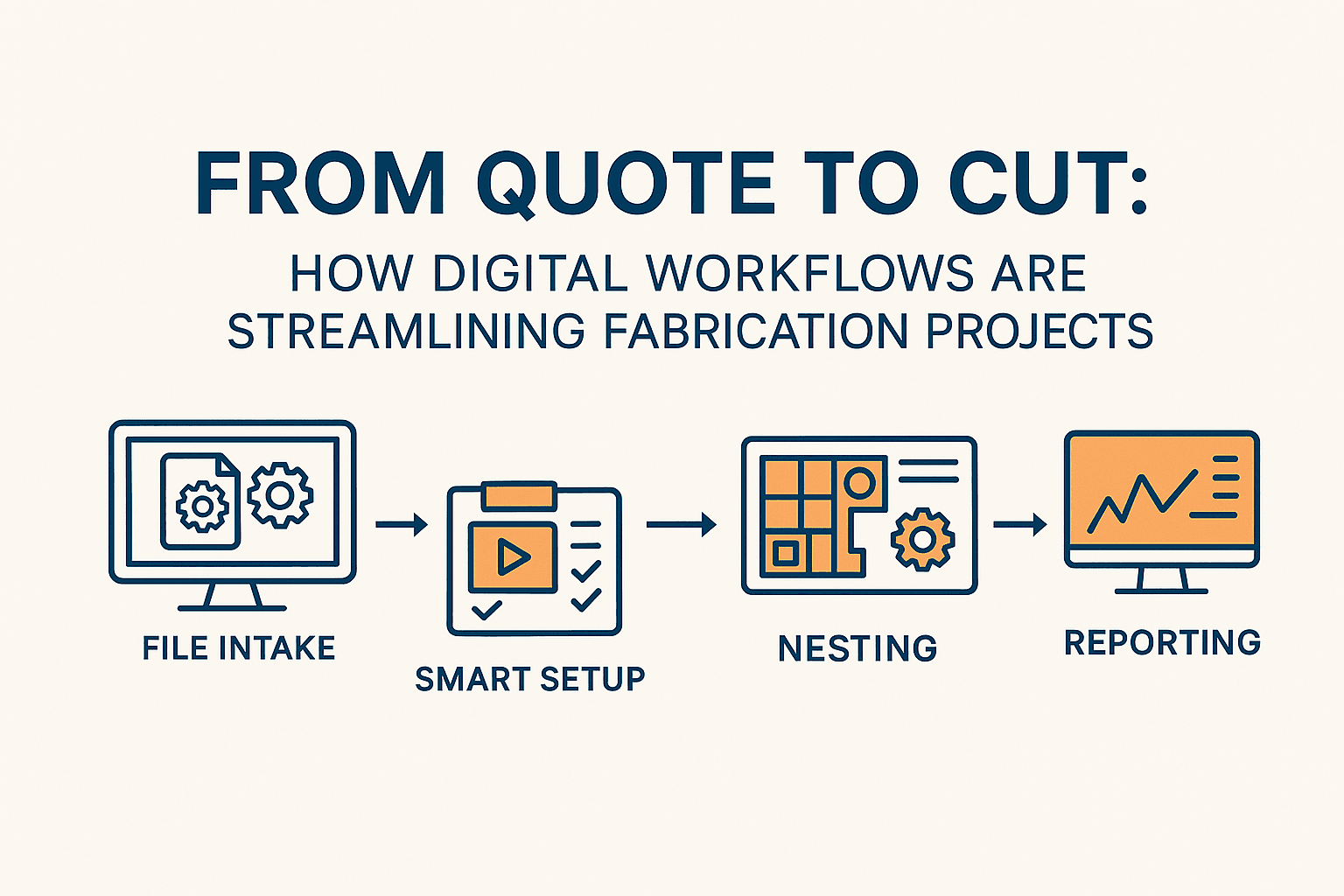

From Quote to Cut: How Digital Workflows Are Streamlining Fabrication Projects

Introduction

Speed, accuracy, and clear communication are the new benchmarks in modern fabrication. Digital workflows—from the moment a quote is requested until the final cut—are transforming how production is planned and executed. By harnessing digital file intake, simulation tools, automated nesting, real‑time monitoring, and detailed reporting, fabrication projects are now completed faster and with far fewer errors. Learn more about our precision engineering on our Solutions Page.

Step 1: Digital File Intake

Hand‑drawn blueprints are a thing of the past. Today, customers submit digital files (DXF, DWG, STEP) directly, allowing our systems to integrate seamlessly with leading CAD/CAM platforms. This integration reduces translation errors and significantly speeds up job preparation. By embracing digital file intake, our processes are in line with the principles of computer‑aided manufacturing, ensuring every design detail is captured accurately.

Step 2: Smart Job Setup

Once the digital files are received, operators can simulate the entire cutting process before any material is processed. They check toolpaths, estimate processing times, and select optimal settings based on our curated material libraries. This smart job setup minimizes trial‑and‑error and protects expensive stock, ensuring each job is set up for success from the start.

Step 3: Automated Nesting and Scheduling

Advanced nesting software automatically arranges part layouts for maximum material efficiency and links seamlessly with your ERP or MES system. This automation queues jobs, optimizes scheduling, and even manages rush orders or last‑minute changes with minimal disruption. These streamlined digital workflows are a vital part of the Industry 4.0 revolution, as discussed in Industry 4.0.

Step 4: Real‑Time Monitoring

With our integrated systems, shop managers can monitor machine health, productivity, and job progress in real‑time—even remotely. Continuous diagnostics and live performance tracking enable proactive maintenance and operational adjustments, ensuring maximum uptime and efficiency on the shop floor.

Step 5: Reporting and Traceability

Every job’s cut history, material usage, and quality logs are automatically recorded and stored. This robust reporting not only supports quality assurance and compliance but also facilitates more accurate future quoting and repeat orders. With comprehensive traceability, fabrication projects become increasingly predictable and efficient over time.

Conclusion

Digital workflows aren’t just the future—they’re the present. By integrating digital file intake, intelligent job setup, automated nesting, real‑time monitoring, and detailed reporting, our cutting technology empowers shops to work faster, smarter, and with fewer errors. For more in‑depth insights on digital transformation in fabrication, check out our Tech Blog. If you need personalized assistance or further information, please visit our Contact page.

Frequently Asked Questions

What are digital workflows in fabrication?

Digital workflows are a series of integrated processes that start from receiving digital design files and continue through simulation, automated nesting, real‑time monitoring, and reporting—all designed to improve speed, accuracy, and efficiency.

How does digital file intake improve production?

By receiving DXF, DWG, or STEP files directly, digital file intake eliminates manual translation errors and accelerates preparation time, ensuring seamless integration with CAD/CAM systems.

What benefits does automated nesting provide?

Automated nesting arranges parts for optimal material usage and schedules jobs efficiently through integration with ERP or MES systems, reducing waste and minimizing production delays.

How does real‑time monitoring enhance operational efficiency?

Real‑time monitoring enables remote diagnostics and continuous tracking of machine performance, allowing managers to address issues proactively and ensure maximum uptime.

Why is comprehensive reporting and traceability important?

Detailed logs of cut history, material usage, and quality help in quality assurance and provide data for more accurate future quoting, supporting consistent repeat orders.