Direct Servo Drive 4000 Pump

Achieve the same 4000 bar cutting speed as a hydraulic intensifier while reducing electrical consumption by half—driving down your energy costs.

Our direct-servo technology runs virtually silent—no high-decibel clatter or hydraulic shock—creating a calmer, safer shop floor without sacrificing power.

Intelligent servo control continuously adjusts pressure and water flow in real time, maximizing abrasive efficiency and surface finish across diverse materials.

Achieve the same 4000 bar cutting speed as a hydraulic intensifier while reducing electrical consumption by half—driving down your energy costs.

Our direct-servo technology runs virtually silent—no high-decibel clatter or hydraulic shock—creating a calmer, safer shop floor without sacrificing power.

Intelligent servo control continuously adjusts pressure and water flow in real time, maximizing abrasive efficiency and surface finish across diverse materials.

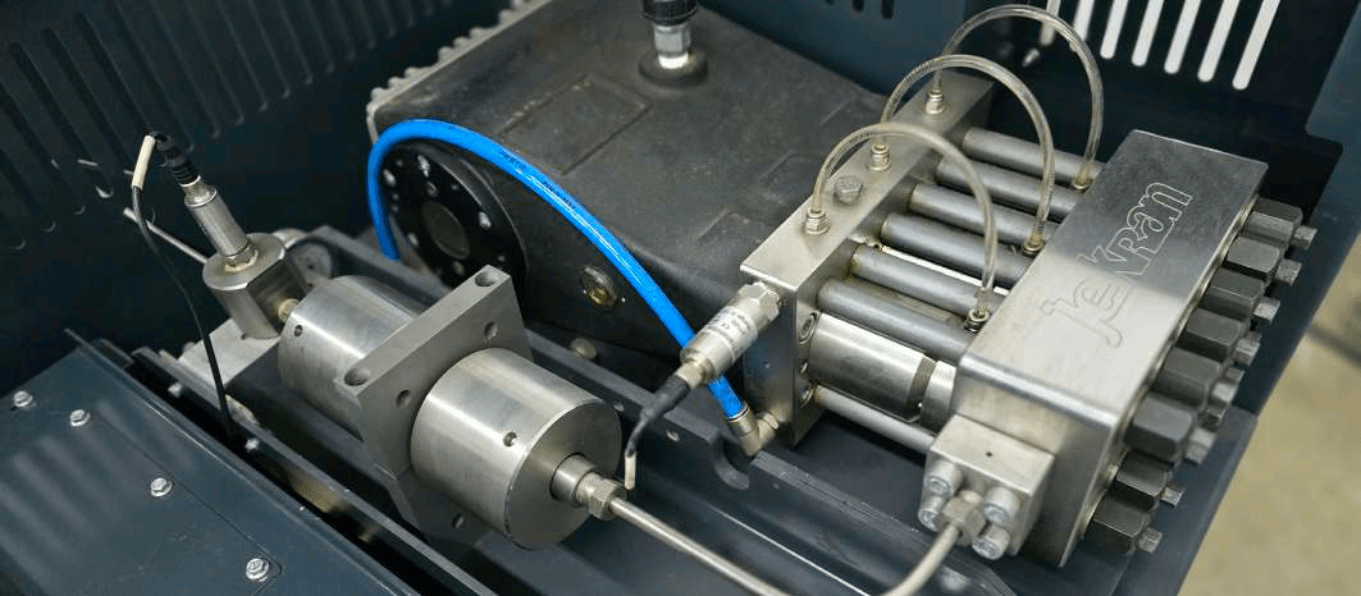

Next-Gen 4000-bar Direct Servo Drive Waterjet Pump

Experience the next generation of waterjet power with our stand-alone Direct Servo Drive 4000 bar Pump—engineered exclusively for OEM waterjet systems using high-precision servo motor technology.

Delivering the same cutting speed and thrust as a hydraulic intensifier while slashing power consumption up to 50%, this pump runs whisper-quiet, continuous and pulsation-free up to 4000 bar (58,000 psi).

Proven in our own cutting platforms, it boasts exceptional reliability, low maintenance and extended service intervals with minimal intervention.

Benefits for Waterjet OEMs

By equipping machines with our 4000 bar direct servo pump, OEMs slash operational costs, boost throughput and create quieter, safer work environments.

Rapid pierce times, optimized abrasive usage and consistent kerf quality ensure peak cutting performance across metals, composites and ceramics.

The pump’s small footprint and plug-and-play controls simplify machine architecture, while embedded diagnostics and remote firmware updates turn maintenance into a proactive, uptime-maximizing process.

Key Features

up to 50% Lower Energy Draw: Achieve equivalent cutting performance to intensifiers at half the electrical consumption.

Ultra-Quiet Operation: Near-silent servo motor design eliminates the high-decibel clatter of hydraulic units.

Continuous Duty at 4000 bar Run 24/7 without heat-soak or duty-cycle limits.

Precision Flow Control: ±0.5% repeatability for consistent kerf widths and smooth edge quality.

Industrial-Grade Materials: Durable martensitic stainless steel pump components, ceramic plungers, and PEEK seals ensure long-lasting performance in abrasive waterjet applications.

OEM-Ready Electronics: EtherCAT, Modbus TCP/IP and analog/digital I/O for seamless machine-control integration.

Built-In Diagnostics Real-time pressure, temperature and vibration monitoring keeps you ahead of maintenance.

4000 Pump Technical Specifications

| Model 22 Direct Drive | Model 30 Direct Drive | |

| Electric Servo Motor Power | 30 HP (22 kW) | 40 HP (30 kW) |

| Efficiency | ≥ 90% | ≥ 90% |

| Output Pressure PSI | 58,000 psi | 58,000 psi |

| Output Pressure Bar | 4000 Bar | 4000 Bar |

| Orifice & Flow Rate | 0.011" / 0.82 gpm (0.3 mm / 3.1 lpm) | 0.014" / 1.1 gpm (0.35 mm / 4.2 lpm) |

| Footprint LxWxH | 43.7" x 31" x 42"(1110 mm x 800 mm x 1065 mm) | 43.7" x 31" x 42"(1110 mm x 800 mm x 1065 mm) |

Frequently Asked Questions

How does the Direct Servo Drive 4000 Pump’s energy consumption compare to a hydraulic intensifier?

It delivers identical 4000 bar cutting power and speed while using up to 50% less electricity, significantly lowering operating costs without compromising performance.

What noise levels and flow characteristics can I expect?

The pump runs whisper-quiet with continuous, pulsation-free flow, eliminating the high-decibel clatter of hydraulic units and ensuring smooth, consistent cuts.

Can it integrate with my existing waterjet CNC or PLC system?

Yes. Standard EtherCAT, Modbus TCP/IP, and analog/digital I/O interfaces allow plug-and-play connection to virtually any waterjet controller or automation setup.

What routine maintenance is required and how long are service intervals?

Routine checks include inspecting seals, fluid levels, and filters at scheduled intervals. With proper filtration (≤ 2 µm) and seal replacements, the pump can run well over 400 hours at full pressure before the next maintenance.

What components ensure the pump’s durability in abrasive applications?

Key parts are made from industrial-grade martensitic stainless steel, ceramic plungers, and PEEK seals, engineered for long-lasting performance under high-pressure, abrasive conditions.

Is customization available to fit specific OEM requirements?

Absolutely. We work with OEMs on bespoke mounting kits, control panel layouts, and firmware profiles to guarantee seamless integration and optimized performance.