Touch screen

Dedicated industrial PC – not prone to viruses or malware

Returns to initial state when reset

Large icon-based system

Simple operation for all levels of CNC knowledge

Large operating buttons

Suitable operation also with gloves

Speed override to adjust feed rate on the fly

Allowing direct response of operator to cutting performance

Shapes database

Pre-set shapes and designs

Ergonomic console design

Placed high from washing area

Protected, whilst accessible control panel

High quality components – Allen-Bradley main motor drive

Ergonomic console design

Smallest machine footprint: 1.5m x 1.5m

Chassis incorporates

Pump assembly

Control panel

Axis movement

Cutting head

Fully welded laser cut chassis – high chassis assembly accuracy

Optical safety curtain

Covered system

No folding bellows to replace. Polycarbonate ‘see through’ shield

Dirt does not impair the operation or cause down time

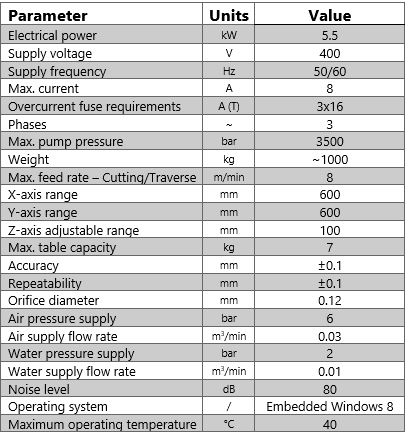

Variable drive pump

Hammelmann German quality pump

Rated 15kW

Suitable for tap water quality – No RO water required

Energy efficient pump – direct drive

3500bar/50760psi at 100% duty cycle

For 0.12mm/0.005” orifice

2 l/min at 3500bar, 0.12mm orifice

5kW Italian Elvem motor

Allen-Bradley variable frequency drive

Reliable operation with guaranteed 1000hr operation between servicing

Locally proven with over 3000hr between servicing

With included charge pump for locations where input pressure is limited

Reservoir included to compensate for irregular water supply

Optimised operation through Allen-Bradley variable speed drive

10µm and 1µm filtering with alarm for filter change

Low operating cost

Variable frequency drive allows pressure optimisation for delicate foodstuffs

Variable speed allows accurate control of pressure on the fly

Accurate and repeatable axis movement

Setup is suitable for production environment

Loading is done from one side

Unloading is done from the other side for continuation of product flow

8m/min cutting speed

All items protected; sensors, cables

Minimal installation and setup time from container to first cut

Easily packaged and transported

Shipped pre-assembled and factory tested through rigorous check lists

No articulated elbows in high pressure line

Expensive to replace

Contribute to reduction in high pressure and reduction in performance

Remote diagnostics through team viewer

Full 304 stainless steel construction

Endless roller belt design

HASP compliant

Twin tray capability

Special anti-splash system

4 cake trays included

Tray contents size 600mmx650mm

Max food weight; 7kg

2 axis movement

Manually adjustable Z-axis height

Pure water waterjet head included