WJFB

Features

– Probably the smallest footprint on the market

– Rugged laser-cut chassis construction

– Accessible 3 sides loading

– Delivery hopper (Variable abrasive flow for precise cutting control)

– Bridge (Stainless steel covers in high wear areas)

– Console (Portable console with touch screen interface)

The WJFB series waterjet is a great value machine for anyone looking at a high end cantilever style model. This machine has the ability to cut through just about any material with precision. Including glass, granite, ceramic, plastic, foam, mild steel, stainless steel, titanium, aluminium, copper, wood etc… The cantilever design allows for much easier material loading and unloading. This design also offers smoother action on the axis with exclusion of moving parts. All axis travel via precision balls screws on square linear rails. All moving parts are covered and protected from splashing for longer lifespan. The chassis is laser-cut and interlocked, then welded for strength, rigidity and accuracy. With easy on-screen display wizards, icon-based touch screen and a built-in material database, the system could not be more user friendly. An integrated material database system means that even un-familiar users can make good use of this machine. Material and thickness are selected, whilst all the other parameters are determined by the CNC.

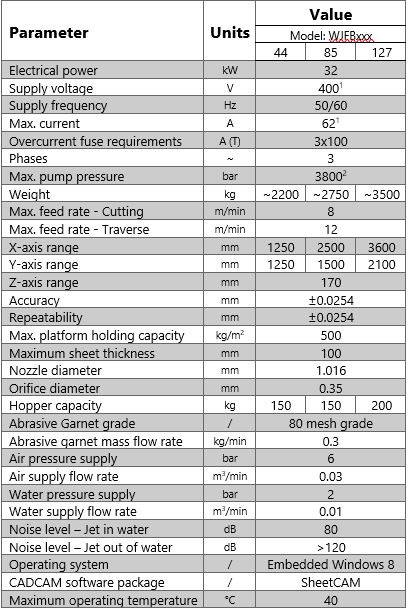

Technical Specifications

Further Reading

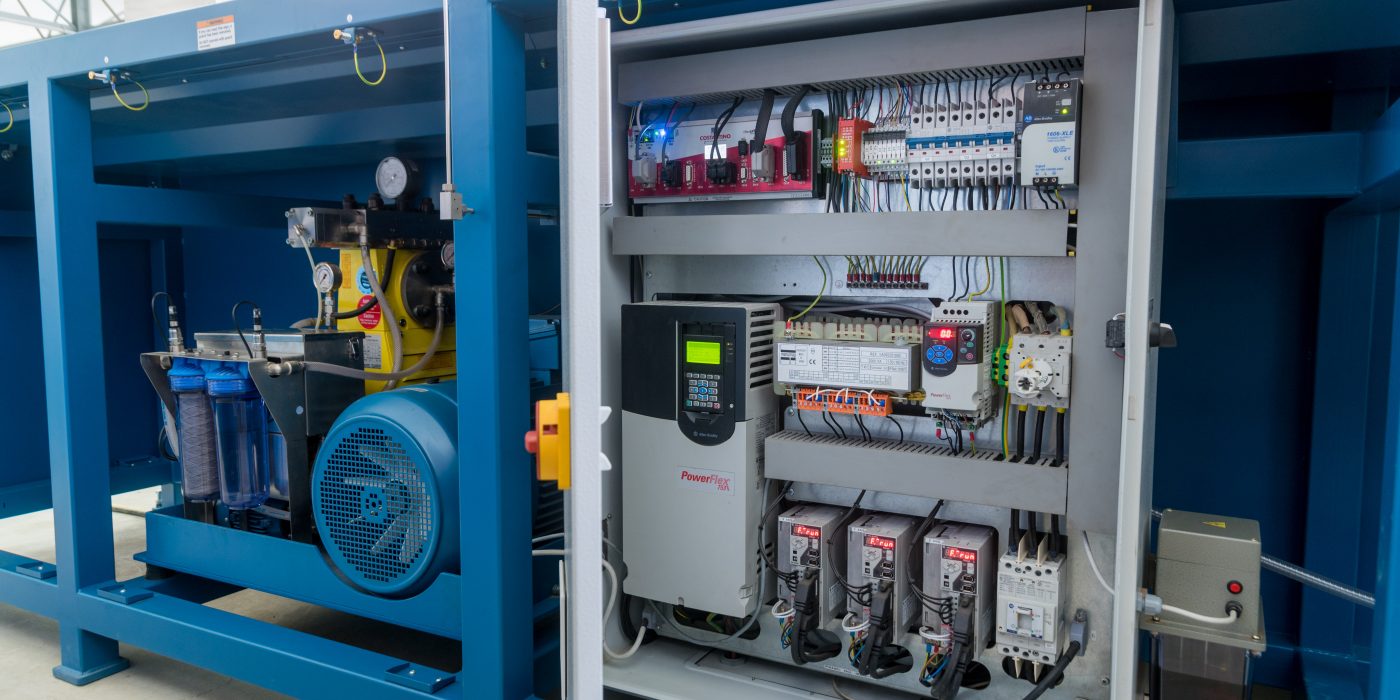

The WJFB series is equipped with a Hammelmann direct drive pump. The advantages of this German engineered pump are size, pressure control, extended time between service intervals and energy efficiency amongst others. The direct drive system is particularly suited for varying pump pressure, such as when cutting brittle or very soft materials, where the pump pressure is required to ramp gradually or be controlled at a specific rate. This is achieved in conjunction with the fully integrated Allen-Bradley inverter drive, attaining maximum control and efficiency to achieve higher production rates.

The machine incorporates the following features:

Touch screen

Dedicated industrial PC – not prone to viruses or malware

Returns to initial state when reset

Large icon-based system

Simple operation for all levels of CNC knowledge

Large operating buttons

Suitable operation also with gloves

Feed rate potentiometer to adjust feed rate on the fly

Allowing direct response of operator to cutting feedback

Material database

Operator selects material and thickness and cutting origin start point

Machine determines:

Feed rate

Cutting garnet delivery rate

Piercing garnet delivery rate

Piercing pressure

Soft piercing/Hard piercing

Cutting pressure

Cutting height

Ergonomic console design

Console can be located anywhere around the machine

Protected and accessible control panel

High quality components – Allen-Bradley drives and components

Ergonomic console design

Smallest machine footprint

Chassis incorporates

Pump assembly

Control panel

Axis movement

Cutting head

Garnet bulk hopper delivery system

Fully welded laser cut chassis – high chassis assembly accuracy

Modular design

Chassis and bridge sizes can be interchanged to suit customer requirements

CNC milled rail bed

Automatic lubrication system

Covered system

No folding bellows to replace. Roller cover used.

Dirt does not impair the operation or cause down time

Y-axis bridge enclosed by stainless steel cover to withstand repeated exposure to aggressive cutting environment

Variable drive pump

Hammelmann German quality pump

Rated 45kW

Suitable for tap water quality – No RO water required

Energy efficient pump

3800bar/55000psi at 100% duty cycle

For 0.35mm/0.014” orifice

4 l/min at 3800bar, 0.35mm orifice

30kW Italian Elvem motor

Allen-Bradley variable frequency drive

Reliable operation with guaranteed 1000hr operation between servicing

Locally proven with over 5000hr between servicing

With included charge pump for locations where input pressure is limited

Reservoir included to compensate for irregular water supply

Optimised operation through Allen-Bradley variable speed drive

10µm and 1µm filtering with alarm for filter change

Low operating cost

Variable frequency drive allows pressure optimisation for delicate components such as marble, glass, composites etc… allowing soft piercing function

Variable speed allows accurate control of pressure on the fly

Accurate and repeatable axis movement ±01mm tolerance

Cantilever system makes this machine particularly suitable for restricted shop floor area

Loading/Unloading of material can be done from three sides

Greatly accessible, unconstrained, removable tank, for easy cleaning and upkeep

12m/min traverse speed

All items protected; sensors, cables

Minimal installation and setup time from container to first cut

Easily packaged and transported

Shipped pre-assembled and factory tested through rigorous check lists

Ball screw transmission

Linear rails support

Auto feed garnet delivery system within chassis

Operation does not need to stop to fill in with garnet

Up to 200kg garnet capacity

10L pressure vessel capacity

Automatic feeding system, PLC controlled with variable potentiometer for accurate configuration according to garnet Mesh used

Low level tank sensor

Proportional control mini hopper garnet delivery to cutting head

Cutting garnet can be adjusted on the fly according to cutting feedback from 0g/min to 300g/min

Laser cross hair for indication of trial movement and to determine part origin

No articulated elbows in high pressure line

Expensive to replace

Contribute to reduction in high pressure and reduction in performance

Remote diagnostics through team viewer

SheetCAM software licence supplied with all machines

Powder coated metal components

Additional Accessories

Accessories include;

Water level height adjustment during cutting to minimise cutting noise

40kW electrical motor for additional cutting power and using a 0.4mm orifice at 3800bar

Automatic garnet disposal system